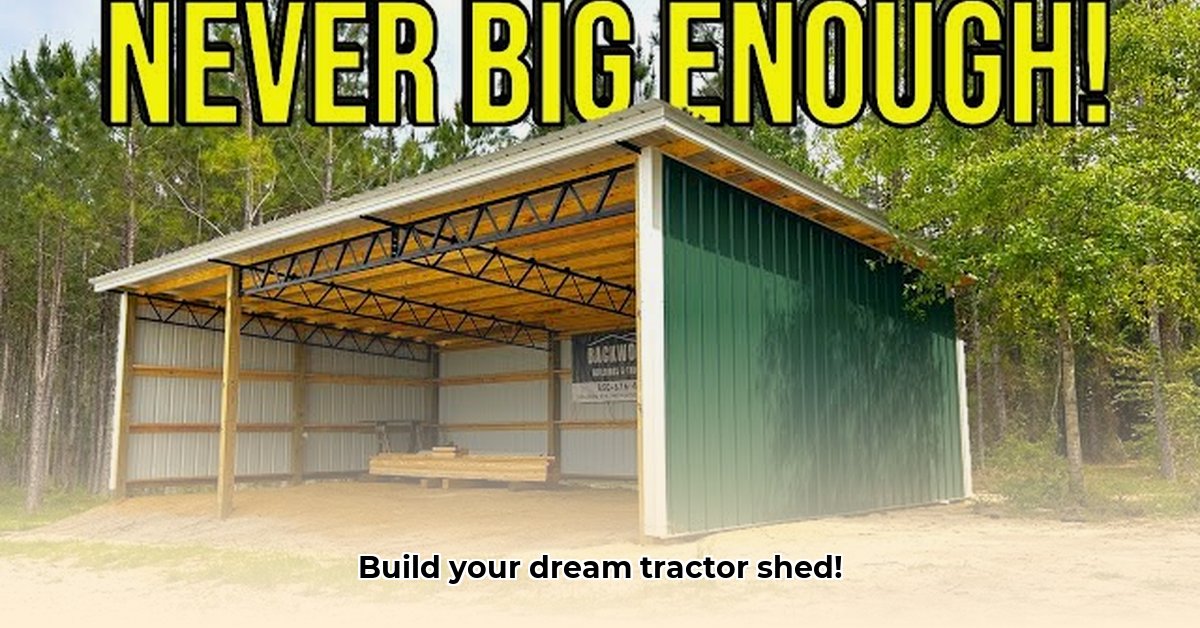

Building a lean-to tractor shed is a rewarding DIY project, even for beginners. This guide provides a step-by-step approach, blending practical instructions with a narrative to make the process engaging and manageable. Let's transform your vision into reality! For more detailed plans, check out this helpful resource.

Planning Your Tractor's New Home: Size, Design, and Legalities

Before you grab a hammer, careful planning ensures success. First, determine the shed's size. Consider your tractor's dimensions, plus extra space for tools or other equipment. Remember, bigger isn't always better—larger sheds require more materials and labor. A simple lean-to design is perfect for beginners: it's less complex than a freestanding shed and typically attaches to an existing structure for support. Did you know that a lean-to shed can often be built with 25% fewer materials than a freestanding shed of comparable size? Before construction begins, check your local building codes and obtain necessary permits to avoid costly setbacks later. This might seem tedious, but it’s a critical first step towards creating a legal, secure structure.

Laying the Foundation: A Stable Start

A stable foundation is paramount for a long-lasting shed. Your options depend on your budget and soil conditions. For smaller sheds on stable soil, compacted gravel provides a cost-effective base. For heavier loads or less stable soil, concrete blocks offer greater stability. Pressure-treated lumber is another alternative, but requires careful leveling. Regardless of your choice, ensure a level surface; an uneven foundation leads to structural problems down the line, potentially compromising the safety of your tractor and anyone near the structure. Spend the extra time to get it right—this is your shed's bedrock.

Framing the Structure: The Shed's Skeleton

With the foundation complete, it's time to build the frame. We'll use pressure-treated lumber for durability and rot resistance. Construct a sturdy rectangle, precisely matching your planned dimensions. Use a speed square to ensure perfectly square (90°) corners; accurate measurements here are crucial for the shed's structural integrity. Did you know that 90% of structural problems stem from inaccurate initial measurements? Double-check your measurements diagonally to confirm accuracy. Secure all connections with heavy-duty screws or bolts; make sure everything is tightly fastened for optimal stability. A helping hand here is invaluable for safety and efficiency.

Raising the Roof: Protection from the Elements

The roof construction of a lean-to is typically straightforward. Use sturdy rafters, spaced according to your chosen roofing material's specifications. Securely attach them to both your frame and the supporting wall. A steeper roof slope improves water runoff, reducing the risk of leaks. Install appropriate flashing at joints and where the roof meets the walls to prevent water penetration; this detail often gets overlooked. Choosing quality roofing materials minimizes future headaches and increases the lifespan of your shed. The added effort pays off in the long run.

Siding and Roofing: Shielding Your Investment

Selecting weather-resistant materials for both siding and roofing is key to your shed's longevity. Metal roofing is a popular choice for its durability and longevity and is easily installed. Install the siding carefully, ensuring a tight fit to prevent water penetration. "A well-sealed shed is essential for protecting your equipment from the elements," says Mark Johnson, a seasoned carpenter with over 20 years of experience. Thorough sealing ensures your tractor stays dry and your investment is protected.

Doors and Finishing Touches: Adding Functionality and Aesthetics

The final step involves installing the door(s). Choose an appropriate size for easy tractor access. Consider adding vents or louvers to enhance air circulation and prevent moisture buildup, a frequent cause of equipment damage. Painting or sealing the shed not only improves aesthetics, but also enhances protection against the elements. A final inspection of all fasteners and repairs ensures a secure, safe, and long-lasting structure.

Material List: A Comprehensive Overview

The following table provides a general guide to material quantities. Adjust based on your specific shed dimensions. Remember to account for possible waste.

| Material | Quantity (Adjust to your Shed Size) | Notes |

|---|---|---|

| Pressure-treated lumber | Varies | For frame, foundation, and rafters |

| Roofing material | Varies | Metal roofing is durable and cost-effective |

| Siding material | Varies | Choose a weather-resistant material |

| Fasteners (screws/bolts) | Varies | Ensure appropriate size and type for materials |

| Gravel/Concrete Blocks | Varies | For foundation (optional, depends on ground) |

| Door(s) | 1 or more | Size depends on tractor access |

Remember safety precautions! Wear safety glasses, gloves, and sturdy footwear. Enlist help for lifting heavy materials.

With careful planning and execution, you'll soon enjoy a solid, weatherproof sanctuary for your tractor!